Do you have any of these problems?

- Expensive raw materials are left at the bottom of the drum

- Liquid often leaks from the seal during transfer

- Do not want to generate pump-derived metal dust

- wear of pump parts quickly reduces capacity

- want to reduce maintenance time

- want to transfer various viscosity liquids with a single pump

- pump operation noise is bothering

Radial vane pump can solve these problems!

Main functions of radial vane pump

Capable of pulling out to the very bottom of the drum

The unique mechanism of this positive displacement pump has a very high self-priming force like a vacuum cleaner and can suction liquid even while biting bubbles.

This pump is very effective for applications such as removing liquid from a vacuum tank or collecting liquid from the bottom of a drum leaving no residue.

High durability and abrasion resistance

The unique sliding structure of the vane and the inside of the casing eliminates deformation and wear of the vane.

In addition, by changing the vane material and specifications to prepared different variations to suit the application and liquid to be handled, wear resistance can be dramatically improved.

Also, the inner surfaces of the casing and liner (sliding parts with vanes) are strengthened by ceramic press-fitting and ceramic spraying, and other technologies based on our extensive experience and achievements have been introduced to improve the durability of the pump body.

CHECK!What is suitable for highly abrasive liquids and slurries? add_circle

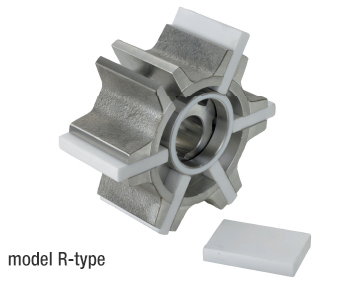

ceramic fitted rotor

By attaching a ceramic plate to the most load-bearing part of the rotor,

its durability greatly improves even when transferring highly abrasive fluids.

ceramic liner inserted casing

By using ceramic inside the casing, chemical resistance, corrosion resistance, and abrasion resistance are improved.

This ceramic has no holes for liquid intake or discharge, so cracking due to heat shock is also less likely to occur.

Resistant to solvents, high temperature, high viscosity liquids, and liquids mixed with slurry!

Various sealing mechanisms

Standard specification is clutch type (SIC/SIC).

It can handle a wide range of high-viscosity liquids mixed with solvents, solvents, and slurry.

knife-edge mechanical seal and stationary mechanical seal can also be installed.

We also have a variety of other shaft seals with different patterns/types based on our accumulated experience, and can select the appropriate one according to the liquid to be handled.

CHECK! Selectable seals (shaft sealing device) add_circle

Standard mechanical seal

Supported models:

RV – 20(P)、25(P)

V – 20(P)、25(P)

R(C) – 40N(P)、40W(P)、50P

V(C) – 40NP、40WP、50P

Edge Mechanical Seal

Supported models: All models

Outside type mechanical seal

Supported models:RV – 20(P)、25(P)

V – 20(P)、25(P)

Lip seal specification

Oil seal specification

O-ring specifications

Capable of transferring liquids of various viscosities and adjusting dispensing volume

This positive displacement pump can be operated at low speeds by using a stepless gearbox or inverter, so it can handle liquids of various viscosities with a single pump by operating it at low speed when handling high-viscosity liquids and at high speed when handling low-viscosity liquids.

Even when the same liquid is handled, the pump can be used as a filling pump by changing the rotation speed to achieve a variable discharge rate.

quick cleaning of wet parts!

The inlet/outlet (port block) and casing can be separated, allowing the casing to be removed while the transfer piping is still attached to the port block*.

Daily maintenance is easy because parts that come in contact with liquid, such as rotors and vanes, can be cleaned in a short time.

*Supported models:

R(C) – 40N(P), 40W(P), 50P, 65P, 80P

V(C) – 40NP, 40WP, 50P, 65P, 80P

quiet operation noise

In addition to the metal parts never coming into contact with each other in the rotating section, the structure is designed to prevent pressure loads during transfer, resulting in very quiet operation.

No need to priming every time

Thanks to high self-priming capacity, priming water is not required each time when switiching drums in transferring liquid from multiple drrums to tank.

For more informationkeyboard_arrow_right

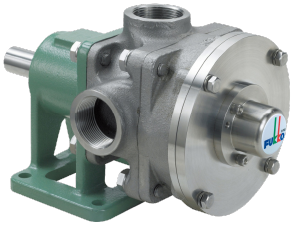

Main specification range

| model | Model R-type, Model V-type |

|---|---|

| bore | 20A~80A / 1S~3S |

| total pump head | Max. 0.5 MPa |

| Discharge volume | Max. 700 L/min |

| Driving system | Direct coupling connection, V-belt drive |

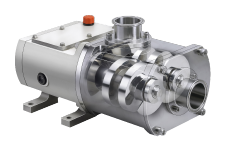

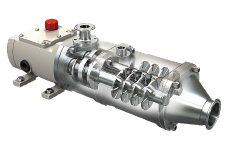

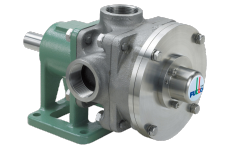

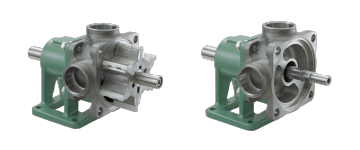

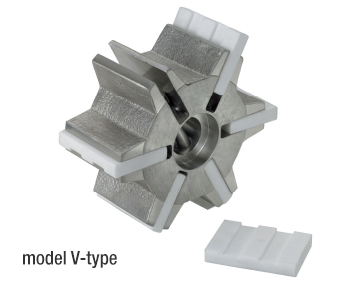

Model R-type and Model V-type

FUKKO radial vane pumps are of two types.

The R-type, with 40 years and 60,000 units of proven performance,

and the V-type, with even higher performance.

You can choose the one that best suits your application.

Forward and reverse rotation can be switched with a single switch.

・The original mechanism (see below) solves performance degradation caused by vane wear.

・For forward and reverse rotation, simply change the direction of vane insertion.

CHECK!Vane automatic pressure regulating mechanism (PAT.P) add_circle

Vane automatic pressure regulating mechanism (PAT.P)

Generally, when the vane wears out, the vane pump loses its sealing ability, causing a drop in flow rate and pressure.

The V-type vane auto pressure regulating mechanism prevents capacity loss because the vane itself behaves in such a way that it maintains sealing even if it wears out.

This results in longer vane life and minimizes running costs.

Operating principle of radial vane pumps

Model R-type operating principle

Model V-type operating principle

Products Explanation Video

Application Examples

Chemicals

Waste oil

Water-based pigments

Paint

Glue

Adhesives

MEK

Acetone

Toluene

chemical agent

Foods

Soy Sauce Moromi

Soy sauce

Soy milk

corsely ground soy bean

Yeast

Chocolate

Koji

Miso

Ketchup

Mayonnaise

Liquid sugar (syrup)

We also have other applications in addition to those listed above.

We also have rental machines available for testing purposes (please contact us for rental costs).

FAQ about Products

Q

- keyboard_arrow_right

- Want to eliminate leakage at the shaft seal.

- Due to the property of liquid I want to be handled, leakage often occurs at the sealing area…

A

Leakage often occurs with ordinary seals especially when transferring water-soluble emulsions and thermosetting liquids.

FUKKO has a wide variety of special seals based on our accumulated knowledge.

We can also handle other types of solutions, so please feel free to contact us.

Q

- keyboard_arrow_right

- Want to increase slurry resistance as much as possible

- We want to pump highly abrasive slurry, but we don’t want to reduce the perfomance of the pump due to wear as much as possible…

A

Various measures can be taken to meet the customer’s operating conditions, such as introducing ceramic liners or ceramic rotors, or changing vane specifications.

Q

- keyboard_arrow_right

- Want to transfer various viscositiy liquids with a single pump.

- We are producing a variety of liquids on a single line, but the viscosity differs.

We have a problem because we need to switch pumps according to the different viscosity of each liquid.

A

Vane pumps are capable of pumping low to high viscosity liquids with a single pump.

We have experience in pumping liquids equivalent to water and up to 100,000 cps.

Q

- keyboard_arrow_right

- The pump’s capacity is declining fast.

- I wish to do something about the uneven wear of the vanes on the vane pump in use…

A

Since the vane and the liner on the inner surface of the casing are cylindrical liners, there is almost no uneven wear of the vanes.

In addition, the V-type has an automatic pressure regulating mechanism that automatically pushes up the worn vanes to seal inside liner with liquid pressure, preventing a reduction in pump capacity and extending the vane replacement cycle, thereby minimizing running costs.

Q

- keyboard_arrow_right

- Want to eliminate ceramic breakage.

- The ceramic in my existing vane pump is often broken, can you do something about it?

A

Unlike ceramic liners from other manufacturers, the liner on the inside of the casing is cylindrical, with no inlet or discharge ports, and the force is applied evenly to the entire liner, eliminating cracking of the ceramic due to heat shock.

Q

- keyboard_arrow_right

- Need a pump with quiet operation noise.

- I have a problem with noise of pump in use.

A

FUKKO vane pumps are free from noise and vibration and achieve quiet operation because there are no metal-to-metal contact areas inside the pump during operation, resulting in smooth pumping.

FUKKO KINZOKU Industries customizes pumps to meet the needs of our customers, so please contact us even if you think it is difficult to realize your project.

We will recommend the best pump after discussion.

Please contact us for special liquids or liquids that you are having trouble with.

Copyright© . FUKKO KINZOKU Industry Co., Ltd. All Rights Reserved.