Do you have any of these problems?

- Solid materials collapse or break during transfer

- The properties of the liquid change during transfer

- Daily cleaning of pumps is time-consuming and labor intensive

- Want to simplify the configuration for CIP cleaning

- The pump is worn out and parts need to be replaced frequently

Twin Screw Pump can solve these problems!

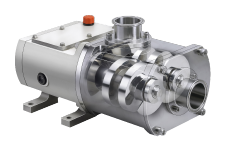

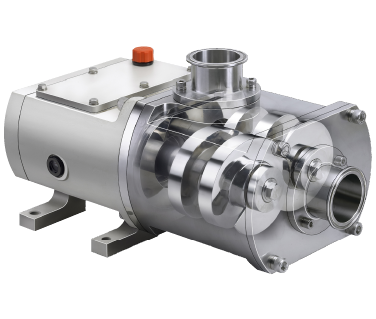

Main features of twin screw pump

High sanitariness

CIP cleaning at an astounding 3600 RPM!

After transfering highly viscous liquids such as paint, food, or cosmetics, the pump can be switched to high-speed operation to clean the inside of the pump without a booster pump by flowing the cleaning liquid.

This is possible because the twin screw pump can rotate at a high speed of up to 3600 rpm, and a single pump can generate the flow velocity necessary for highly efficient CIP cleaning.

Please also refer to the following “Easy Disassembly and Cleaning” page for examples of use.

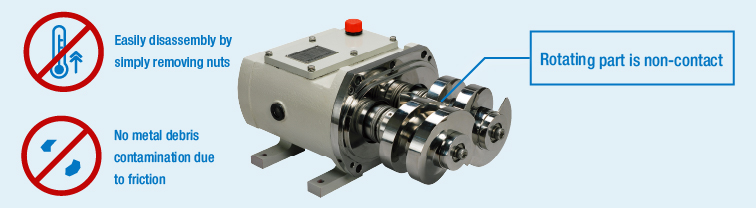

Reducing the Time and Burden of Disassembly and Cleaning

Twin screw pumps can be disassembled, cleaned, and reassembled quickly after use because the liquid-contacting parts can be completely exposed by simply removing the casing.

Particularly, the SQB type with stud bolts can be easily disassembled by simply removing the nuts, thus greatly reducing cleaning time. In addition, the slide bar type can be removed without lifting the casing, which reduces the physical burden.

At production sites where daily disassembly and cleaning is required, the work time spent on disassembly and cleaning can be significantly reduced compared to conventional systems.

Click here for imformation about easy disassembly and cleaning

No Shear / Less Shape Damage

The transfer mechanism is designed to prevent shear (force that twists the object) on the object in transfer, so that even when handling substances that tend to change its shape or property due to force applied to the liquid, the transfer can be performed with minimal alteration.

Transferring liquid without agitation

The structure of the pump is designed to pressurize the object to be transferred while pushing it forward, so that no shear is applied to the object.

This mechanism makes it suitable for transferring delicate liquids that are prone to change in quality, or food products whose taste or texture may change if mixed with other liquids.

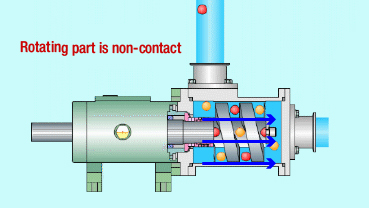

Rotating parts do not contact each other

The rotating parts of the pump do not contact each other, so the screws do not come into contact with each other during operation and metal debris does not get mixed in.

Also, frictional heat is not generated by the contact of the screws, so there is no change in liquid quality due to heating of the liquid during transfer.

Less frequent parts replacement

Less frequent parts replacement

Even in slurry liquid transfer, which parts wear heavily due to liquid contact, the twin screw pump can compensate for the reduction in capacity caused by parts wear by increasing the pump’s rotation speed.

This reduces the frequency of parts replacement, making it possible to keep running costs low.

Quiet operation

The non-contact pump does not produce any kind of frictional noise, and its structure is designed to reduce the load on the pump for smooth transfer, so it is very quiet in operation.

High-speed operation even when transferring high-viscosity liquids

The mechanism smoothly sends the substance forward, so the pump can be operated at high speed as needed, even when transferring highly viscous liquids such as starch glue

Case Studies

Foods

- For quality improvement

Chocolate - For transfer without stirring

Liquid egg

Ground meat

Miso

Ketchup

Pharmaceuticals and Cosmetics

- For stable supply of row materials

Eye drops - For CIP cleaning to improve productivity

Medical jelly

Cosmetic cream

Chemicals

- For reduction of maintainance frequency

Carbon slurry - Without clogging fibers

Pulp - To suppress foaming of liquid

Detergent

We have a variety of other applications in addition to the above.

We also have rental equipment available for testing purposes (please contact us for rental costs).

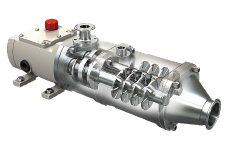

Operating Principle

This positive displacement pump generates self-priming force by rotation of two screws that are not in contact with each other.

The liquid (fluid) confined in the space partitioned by the two screws and casing is continuously pushed forward with the rotation of the screws.

This mechanism is like a piston pumping fluid out of a casing, so there is almost no force applied perpendicular to the shaft, and the fluid can be pumped smoothly without shearing or agitation.

Click here for detailed informationkeyboard_arrow_right

Products Explanatory Video

Introducing a case study that 85% of water in the amount was reduced in soy beans transfer.

FAQ about our products

Q

- keyboard_arrow_right

- Want to avoid contaminatio.

- I am troubled by the risk of contamination from metal or rubber debris derived from pumps in use.

A

This is a positive displacement pump which the screw does not contact other parts inside. In addition, thanks to the principle of pumping, shafts are less bended even when pressure is applied inside the pump, thus avoiding contact between the screw and casing during pumping, and thus eliminating contamination.

Q

- keyboard_arrow_right

- The liquid to be handled is very abrasive.

- We need to overcome the task that pump parts are worn out and the pump in use quickly lose capacity…

A

The frequency of replacement of major parts can be reduced thanks to a structure that allows recovery of capacity that has decreased due to wear of parts by increasing the rotational speed.

Q

- keyboard_arrow_right

- Want to reduce the time and effort required to clean the pumps.

- We are doing CIP cleaning but the dirt removal is insufficient and/or too much work to disassemble and clean after use is needed.

Can you do something about it?

A

Screw pumps can rotate at high speeds and allow cleaning fluids to flow at high velocity, which dramatically improves CIP cleaning efficiency.

Even when the pump must be disassembled for internal cleaning, the structure allows the parts that come in contact with liquid to be exposed simply by removing the casing, so disassembly and assembly are not burdensome.

Q

- keyboard_arrow_right

- I want to make disassembly easier.

- Large pumps are very hard to disassemble. Can you make it easier to disassemble them?

A

The slide bar attached model solves this problem by using two slide bars to pull the casing like a drawer for easy disassembly without coming in contact with the screws.

The stud bolt type can also be used to further reduce the time and effort required for disassembly, making the work even easier.

Q

- keyboard_arrow_right

- Do not want to change the quality of liquid or solids.

- If the liquid quality changes during transfer or the shape of the solids in the transferred liquid is destroyed, the quality of the product will deteriorate.

I want to avoid agitation and shearing…

A

Screw pumps use the in-tube transfer system, a mechanism that continuously pushes the liquid forward, thus avoiding shearing or agitation of the liquid.

This means that even delicate liquids that are prone to deterioration can be pumped smoothly.

Q

- keyboard_arrow_right

- We want to avoid bridging.

- We have trouble with bridging easily occurring at the feed inlet because we are transferring low-fluidity materials.

A

Specifications with paddles can solve this problem.

The pump is equipped with a feeder paddle to prevent bridging in the hopper at the top of the feeding port. This feeder paddle loosens and homogenizes cake-like and pasty materials with low moisture content and close to solidity, and feeds them smoothly into the pump.

The material fed inside the pump is smoothly transferred to the discharge side by a screw conveyor attached to the shaft part.

Q

- keyboard_arrow_right

- Liquid has no fluidity and cannot be transferred.

- I want to transfer a liquid that has no fluidity, can you support this?

A

For handling ultra-high viscosity materials with low water content, cake-like materials, etc. that do not flow, we offer a twin-screw pump (SQW type) with a screw conveyor. For details, please click here.

Q

- keyboard_arrow_right

- I want to solve the leakage.

- We are handling a liquid that tends to leak from the shaft seal area, and we are having trouble with frequent liquid leakage.

A

Leakage at the sealing part tends to occur when transferring liquids with curing properties, adhesives, water-based paints, liquids with extremely unstable physical properties such as latex and emulsions and highly concentrated slurries.

Screw pumps are less prone to leakage because the negative-pressure transfer reduces the load on the shaft seal.

In addition, we provide various types of seals for applications that cannot be handled with conventional seals, so please ask us about our seals.

Q

- keyboard_arrow_right

- I want to handle dry operation.

- There are situations in which the pumps must be operated dry due to the conditions of use, Can you handle it?

A

Dry operation is possible by changing the shaft seal to a dry-compatible seal or quenching specifications, since the two screws, and the screw and casing do not contact each other and do not burn even if operated dry.

Q

- keyboard_arrow_right

- I want to apply enough discharge pressure.

- What is the limiting pressure for a screw pump?

A

Screw pumps can be customized to suit the conditions of use up to a maximum discharge pressure of 2.0 Mpa.

Q

- keyboard_arrow_right

- I want to reduce pulsation during transfer.

- We are having trouble with frequent pulsations in the pump we are using.

A

Screw pumps continuously transfer material to the discharge direction using an in-cylinder screw to achieve smooth transfer with no pulsation.

FUKKO KINZOKU Industry, we customize our pumps to suit our customers’ needs, so please contact us even if you think it would be difficult to realize your project. We will discuss with you and recommend the best pump for your needs. Please contact us for special liquids or liquids that you are having trouble with.