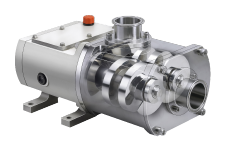

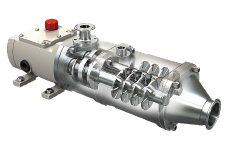

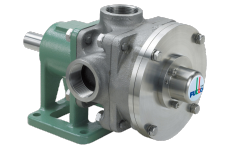

Main features of radial rubber pump

Available even if air or gas is mixed in liquid

The self-priming system enables suction even if air or gas is mixed in the liquid.

Even liquid remaining at the bottom of the material container is sucked up completely.

Slurry contamination and viscous liquids are also acceptable

This high flexibility impeller enables the pump to transfer even slurry or viscous liquids.

Simple structure and easy maintenance

It’s extremely simple structure make it easy to handle and maintenance.

Examples of application

Industrial field

To transfer industrial chemicals such as organic solvents, chemical solutions for dyeing, plating, etc.

Oil Industry field

To transfer low viscosity oil such as kerosene, diesel oil, spindle oil and hevy oil.

Other

For various water supply, drainage, and chemical treatment

Other than the above, our products are also used in various other applications.

Main specification range

| bore | 20A ~ 50A |

|---|---|

| total pump head | 0m ~ 20m |

| Discharge volume | 45L/min ~ 300L/min |

| Drive system | Directly connected to motor |

Detail

- Type of FX model

- Dimensions

- Performance curve

| model | Pump Bore Diameter (mm) |

Motor (Totally enclosed outdoor fan, outdoor type) |

Discharge Volume – Total Pump Head 50Hz(1450rpm) |

Discharge Volume – Total Pump Head 60Hz(1750rpm) |

|---|---|---|---|---|

| FX-20 | 20 | 200V 0.75kw | 45L/min×10m ~ 35L/min×20m |

55L/min×10m ~ 45L/min×20m |

| FX-25 | 25 | 200V 1.5kw | 75L/min×10m ~ 50L/min×20m |

90L/min×10m ~ 60L/min×20m |

| FX-40 | 40 | 200V 1.5kw | 130L/min×10m ~ 80L/min×20m |

170L/min×10m ~ 120L/min×20m |

| FX-50 | 50 | 200V 2.2kw | 250L/min×10m ~ 180L/min×20m |

300L/min×10m ~ 230L/min×20m |

Click on each product number to view its external dimensions and weight table.

- FX-20

- ・FX-20

・FX-20-M (Motor capacity 0.75kw)

- FX-25

- ・FX-25

・FX-25-M (Motor capacity 0.75kw)

- FX-40

- ・FX-40

・FX-40-M (Motor capacity 1.5kw)

- FX-50

- ・FX-50

・FX-50-M (Motor capacity 2.2kw)

・FX-20

・FX-25

・FX-40

・FX-50

Copyright© . FUKKO KINZOKU Industry Co., Ltd. All Rights Reserved.